1. Gain Real-Time Data Visibility

Quick decision-making is the backbone of efficiency. When executives have access to the information they need when they need it, they can use that data to make informed decisions. Yet, C-suite leaders aren’t the only ones who can leverage ERP system software to improve efficiency. This software can actually provide every user in every department with easy access to the data they need.

This means department leaders can stay abreast of compliance issues, traceability concerns, and more. In addition, customer service reps can pull up a client’s history in a matter of seconds, enabling them to offer a more customized level of service.

Another example is sales and marketing. These departments can leverage real-time data to access account histories and determine where a lead stands in the purchasing funnel.

Overall, everyone knows where to go for accurate data, and they’re all going to the same place: customized ERP dashboards.

2022 Top 10 Manufacturing ERP Systems Report

Which manufacturing ERP systems have the strongest functionality? Learn about the systems with the most advanced capabilities in our unbiased report.

2. Improve Production Scheduling

With effective production scheduling, manufacturers can ensure that all incoming materials are used in a timely manner. Otherwise, excess inventory would accumulate, which could hinder productivity.

Companies can use ERP platforms to plan every step of their production process. They can manage all aspects of procurement, pricing, and raw material payment.

In addition, they can check staff schedules, machine usage schedules, and routine maintenance activities to make sure all resources are in place to maximize production.

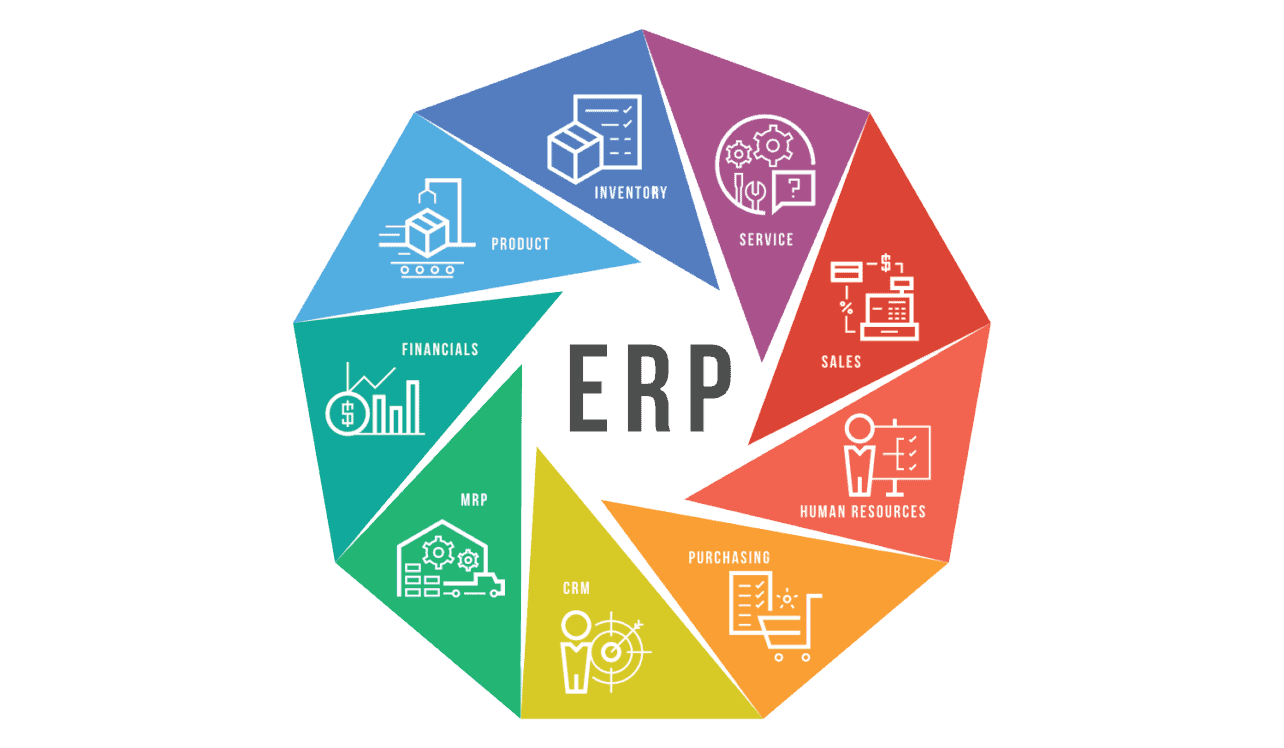

3. Optimize Inventory Management

The inventory management functionality within ERP systems allows manufacturers to maintain a balanced, well-stocked warehouse. In this scenario, they rarely end up with excessively more raw materials than they need, and they rarely have to struggle with shortages.

Manufacturing ERP system provide real-time visibility into work orders as they come in. Users can use this data to manage inventory requirements and make sure the right resources are in place at the right time to meet those needs.

These accurate insights can help minimize outages, which increases customer satisfaction. These insights also reduce overstocks since employees know precisely which materials to source, even if that means relying on multiple suppliers to meet those demands.

4. Enable Global Supply Chain Management

For global manufacturers, it can be a challenge to manage supply chain operations across multiple locations, time zones, and currencies.

Handling these nuances manually can be a logistical nightmare and leaves too much room for human error.

Using a manufacturing ERP system, teams can automate these logistical supply chain management processes and free up employees to proactively address other supply chain issues.

5. Standardize Workflows

When everyone relies on the same ERP platform to do their jobs, workflows become standardized and consistent. This cuts down on the amount of overlap and re-work that occurs and allows team members to collaborate with ease.

Many workflows require coordination between multiple departments. A few examples are safety checks, compliance monitoring, and quality controls. By automating these workflows with an ERP solution, everyone works off the same set of data, so there’s a single source of truth. This keeps production standards high and mitigates internal conflicts.

6. Improve Customer Service

Many ERP portals have designated customer sections, where users can log in to inquire about details such as product availability and pricing. Then, they can use that data to quickly place an order.

Manufacturers can analyze these inquiries to plan more accurate production schedules that streamline delivery. The ability to pull and ship an order almost immediately after a customer places it can be a competitive advantage. It builds long-term loyalty and can be a major selling point for on-the-fence prospects.

Especially in organizations with a global supply chain and millions of dollars in revenue, order automation is the way to go. Making large-scale purchases over the phone isn’t nearly as safe or secure.

7. Enable Continuous Improvement

Manufacturers need the ability to track the performance and profitability of each job they do. These insights can be difficult to glean without a single source of truth.

Thankfully, most ERP manufacturing systems now include built-in business intelligence (BI) and data analytics that track progress at the most granular level. This enables users to clearly see which jobs and clients are the most profitable, so they can focus their efforts.

TSVMap is here to help grow manufacturing processes and consult your IT Solutions that way we can make it more effective and efficient. So if you need :IT Solutions, Consultant, ERP Systems, MRP Systems, Automations, or Cyber Security. Contact us today at 864-991-5656 or Email info@tsvmap.com

Article Provided By: Panorama Consulting

0 Comments